|

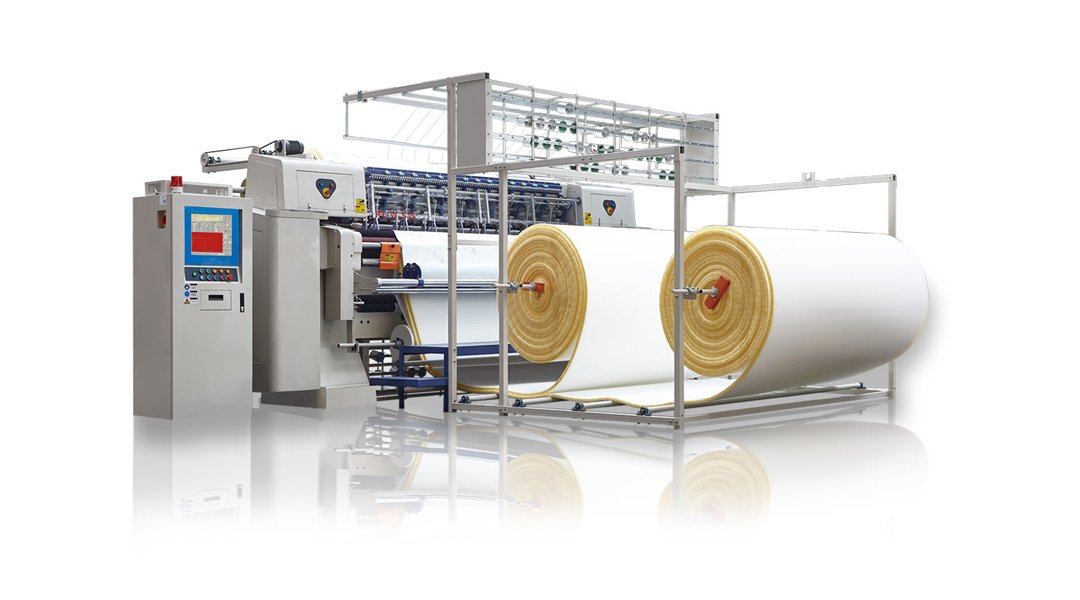

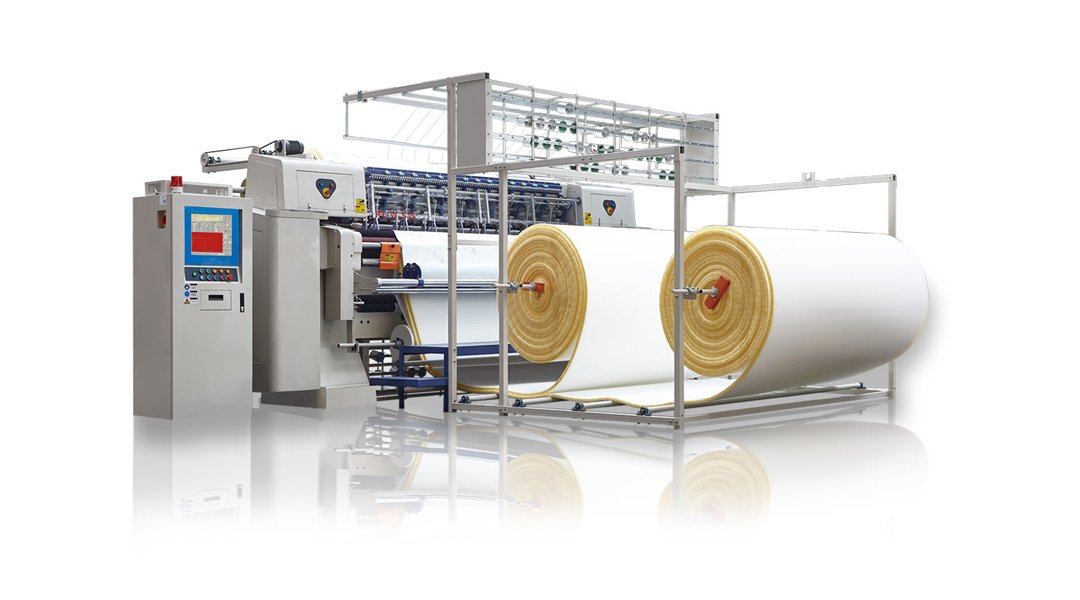

Mainly used for various patterns on quilted high-end mattresses, bedding, home decoration and other products

1. New type of wire rack structure, low noise

2. Optimize the mechanical structure, increase the speed and increase the output

3. The press plate can be adjusted according to the thickness of the material by one button

4. The quilting stitch is tighter, and the quilting pattern has a stronger three-dimensional effect

5. The needle row and pressure plate adopt a cam-free double swing arm movement mechanism to avoid the occurrence of lubricating oil staining the fabric

6. Multi-step independent patterns (covering 360°, 180° quilting patterns)

7. Infrared inspection of surface and bottom thread breaks, automatic shutdown, automatic needle raising and CNC speed regulation

8. Pass the CE certification of safety protection standards

9. High rigidity body, high machine running speed, light vibration, low noise, no impact

10. A new generation of computer control system, high quilting accuracy, no need to adjust the parameters or modify the pattern too much during the quilting process

11. CAD drawing method, accurate graphics, convenient and quick

12. Powerful pattern combination and multi-stride function, which can quilt different patterns in each row in mattresses of various sizes

13. Condition monitoring, machine operation status is clear at a glance

|